Aluminum Roofing Sheet Roll Forming Machine Double Layer Metal Tile Making Machine In China

The steel tiles produced by roof tile forming machine look beautiful, elegant and noble. They are widely used as the roof of garden, factory, hotel, exhibition center and villa,etc.

Tile Roll Forming Machine Material:

1. Electric elements: Mitsubishi PLC & transducer from Japan.

2. Anti-rust roller: High grade No. 45 forged steel. Plated with 0.05mm hard chrome

3. Well resisting active shaft: High grade No. 45 carbon wrought steel.

4. Cutter blade: Cr12 mould steel with quenched treatment

5. Precision: shafts are tooled by grinding machine at least twice. Rollers are CNC processed.

Offer Factory Price Roof Tile Roll Forming Machine |

Item | Specification |

Material | Type | Pre-painted steel coil & galvanized coils |

Thickness | 0.18-0.8mm |

Yield strength | 235Mpa.Q345Mpa, Q550Mpa |

Roller material | No.45 forged steel |

Forming speed | About 15-20m/min |

Output speed | 13-15m/min |

Speed adjusting mode | AC Frequency |

Roller drive | Decelerating motor + Chain drive |

Cutting mode | Hydraulic cutting |

Cutter material | Cr12 mould steel |

Length measurement | Encoder |

Control mode | Panasonic or Delta PLC |

Operating mode | Button + Panasonic/Delta Touch screen |

Main motor | 5.5KW |

Hydraulic station motor | 3KW |

The profiles can be sustomized. If you don't have any idea, Just tell us your country, we can provide advices for you.

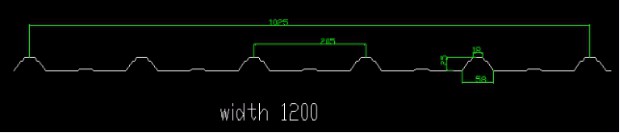

Profiles for reference.

Factory:

We have established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard. We are the leading manufacturer of roll forming machine in China. We manufacture various kinds of roll forming machines for producing such products as Roof Tile, Wall Panel, Roofing Corrugated Sheet, Floor Deck, C & Z Purling, Highway Guardrail, Sandwich Panel, Container Board, Car Panel, Roll Shutter Door, Downspout, Decorated gusset, Steel Pipe, etc.

Loading:

FAQ:

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

7) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are ALIBAB’s Gold supplier with BV assessment (Audit report can be provided).

We join Alibaba Trade Assurance.

8) What should I provide if I`d love to customized my machine?

A: To customize machine, we`d love to know:

1. Profile drawing

2. Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage: designed per your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker

Have no idea about them?

We will be glad to recommend machines ----Just let us know your country!

Any questions, email or call me drectly. I will try best to help you.

Paige

Skype:

WhatsApp:+86-or